Precision Machining of Aluminum

Gia Công Nhôm Chính Xác

Home >

Under thorough quality control, including prototype development products.

We can meet a wide variety of needs from 1-piece to medium production.

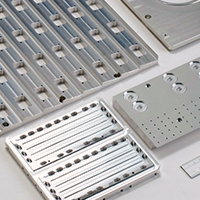

SAMPLE 01

Parts for Semiconductor Manufacturing Equipment

Technical features of semiconductor-related processing are combined machining and micron level accuracy.

Our technologies, the mirror polishing and the strain-controlled, are suitable for this field.

Semiconductor wafer arm: 1~3mm in thickness, flatness within 0.03

Adsorption Plate: 350mm in diameter, flatness within 0.02, small diameter (0.1~0.5mm) holes more than 5000, surface roughness of Ra0.03.

Vacuum cabinet: squareness, flatness and parallelism within 0.02

In this field, combined manufacturing such as surface treatment is required, though we solve technical issues through our network.

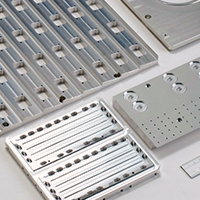

SAMPLE 02

Parts for Liquid Crystal Device

Aluminum parts for LCD-related devices are mainly large plate (max 1000×170mm) drilling. The mirror polishing and own developed jig are suitable for them.

LCD display is commonly easily broken and formed a step by processing large extent pocket but we have the advantage of grooving thin plate (0.1~0.3mm) and keeping its thickness.

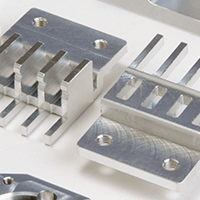

SAMPLE 03

Optical Electronic parts

Aluminum parts for this field requires small diameter holes and micron level accuracy and our micro fabrication technology can deal with them.

Especially, as for complex products to chuck, a small or thin work piece and so on, we provide an integrated manufacturing system from prototype to mass production.

SAMPLE 04

Parts for Medical Devices

Aluminum parts for medical devices are required micron level of accuracy, flatness, parallelism and squareness.

We meet the requirements by our technologies, the mirror polishing and strain-controlled.

As another examples, we provide a polyhedron with the surface roughness of Ra 0.05 and perform grooving thin wall (1~2mm).

SAMPLE 05

Industrial Robots

Duralumin(A7075, A6061 and A2024) are widely used for aluminum parts in robots-related industry.

Our skilled craftsmanship are enable to maintain high accuracy though they have characteristics of thermal deformation and easy to strain.

Our products are used a lot in renowned robots which require high precision.

We design and develop for customer’s requests like reduction in weight.

We provide the best solutions to you.

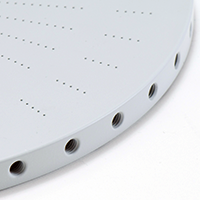

SAMPLE 06

Surface Treatment Technology

There are many surface treatments for Aluminum such as Alumite treatment to create coatings for the aluminum surface, Teflon coating for non-stick and anti-corrosion, Nickel plating, Non-Chromium Anodine coating, or Hard chromium and Anodizing Hard anodizing.

Machining techniques and coating methods for part surfaces will be better if customers provide all necessary information about the surface and requirements of the workpieces, jigs after finishing treatment. .

To get the best surface treatment quality there is a discussion about the product right from the manufacturing and processing stages.